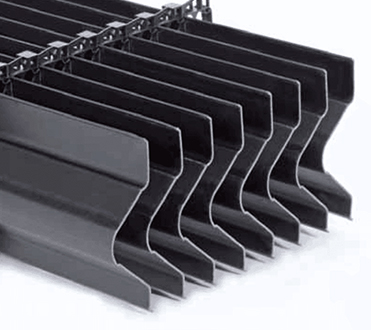

DRIFT ELIMINATORS

The droplet eliminator is able to remove the water droplet from the airstream avoiding to get water accumulation downstream of it, in the duct or inside and air handling units providing in this way also higher air quality removing possible causes of corrosion or growth of bacteria and mildew. It is designed to capture large water droplets caught in the cooling tower air stream.

It aids in the removal of water droplets from air stream in a cooling tower. They work by changing the direction of the airflow and causing the entrained water droplets to impact the walls of the eliminator.

The cooling tower industry uses drift rate to compare drift eliminator performance, a relationship that correlates droplet capture efficiency to the water circulation rate in a tower.

The drift eliminator is one of the cooling tower parts it is used to minimize the amount of process water loss within the cooling tower for resource usage efficiency as well as keeping an eye on environmental concerns.

CREATIVE COOL TOWERS drift eliminators are specifically designed to achieve maximum drift removal efficiency in both crossflow and counter flow tower applications with various product options available to minimize pressure drop, drift loss, cost or a combination of all three. In counterflow style cooling tower the drift eliminators are fitted horizontally near the top of the tower & in crossflow cooling towers they are fitted vertically on the inside of the tower.

Cellular Drift Eliminators are made from PVC material that meets CTI standard 136 and UV protected. These PVC compounds have outstanding resistance to weather exposure, and are nearly impervious to chemical degradation by alkalis and acids, grease, fats, oils and biological attack. PVC has an excellent fire rating due to its self- extinguishing characteristics.

Unlike other drift eliminators Creative Cool Towers cellular drift eliminators have significantly lower pressure drop than dual purpose eliminators. In the crossflow cellular drift eliminators, they provide an upward flow path and a steep water drainage angle that directs the collected drift back to the wet section of the tower even when impacted by water spray.

Our quality centric approach has helped us in offering a wide range of Cellular Drift eliminators. This is designed to capture large water droplets caught in the cooling tower air stream. Our offered product is known for its impeccable performance, low maintenance and long operation life. In addition to this , clients can easily avail these cellular drift eliminators from us at pocket friendly prices. We provide these drift eliminators in different technical specifications by keeping in mind the needs and requirements of the buyers.

TECHNICAL SPECIFICATIONS

| CHARACTERSTICS | CCT130/CCT-S146 |

|---|---|

| Material | Rigid PVC |

| Maximum Face Velocity | 4.5 m/sec |

| Module Length | Can be chosen in 600-mm increments. Max suggested length 1800-mm |

| Module Depth | 130 / 146 mm |

| Pitch | 20 mm |

| Maximum Spacing of Support with standard thickness of sheets | 800 mm |

| Directional changes for air flow | 3 |

| Standard Thickness (Corrugated/Plain) | 0.3 mm/0.4 mm |

| Average Weight | 7.6 / 8.5 kgs/m2 |

| Expected Drift Loss | < 0.001% / 0.0005% of circulating water |

| Maximum Continuous Temperature (deg Celsius) | 55C |