Film Fills

Film Fills are the most efficient filling media available for cooling towers. Creative Cooling Towers is into manufacturing and marketing of various types of fill designs suitable for different water quality. The usage of film fills- in both counter flow and cross flow cooling towers allows relatively smaller sized towers to cool and equivalent amount of water compared to cooling towers using splash fills. The high thermal performance and low pressure drop are balanced by appropriating the engineered microstructure design and maintaining the highest manufacturing standards.

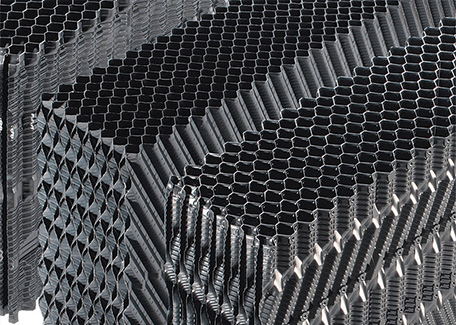

Film fill comes in sheets of material, shaped into corrugated pattern. This pattern enables the water to travel across it smoothly and quickly. To create various thickness and heights, this fill can be stacked . In other words, film fill can be customized to fit the needs of any particular cooling tower.

Advantages

- Minimum resistance to air flow

- Good distribution of water leads to turbulent mixing of air and water to maximize heat transfer

- Reduced fill height and greater cooling capacity results in lower power consumption

- Erosion and rotting resistant and long lasting( 10-12 years of service time in good quality water)

- Easy to glue at site, reduces transportation cost

- Ability to fold the edges of the sheets providing strong edges

CCT FILL MODEL’CCT-12’: is a cross fluted film fill that works on the principle of water droplets developing a fine film of the surface of the media. It is designed for application in the HVAC industry as well as other industries where the quality of make up water is one with CCT.

CREATIVE COOLING TOWRS USING CCT’-12’ fills must have little to no contamination from oil, grease or process dust. It is a cross fluted film fill that works on the principle of water droplets developing a fine film om the surface of the media.

TECHNICAL SPECIFICATIONS

| CHARACTERSTICS | CCT-12 |

|---|---|

| Primary Cooling Towers Application | Counterflow |

| Flute height | 12 mm |

| MOC | Rigid PVC (Virgin and reprocessed) |

| Longitudinal pitch | 37.5 mm |

| UV Stabilization | White - Titanium Dioxide Black - Carbon Black |

| Spiral angle | 28o |

| Std. Sheet size L x W | 600 mm x 300 mm |

| Recommended Max Fill Sheet size L x W | 1200 mm x 600 mm |

| Surface area per unit volume | 258 m2/m3 |

| Standard Weight | 26.5 Kgs/m3 |

| Maximum continuous Operating temp. | 55 oC |

| Minimum Fill Sheet Finished Thickness | 0.175 mm |

| Standard Followed for Material properties | CTI STD-136 |